Background of “GreenFan” development

For the first five years after its founding, BALMUDA maintained an intense focus on creating products just as they envisioned them. After a global financial crisis and change in market needs, they realized they would also have to create products that appealed to a wider range of people. Gen decided if the company’s end was at hand, then this was the last opportunity to develop a product he dreamed about for years: an electric fan.

Gen had long been interested in electric technology, driven by awareness of climate change and energy issues. “Perhaps,” he mused, “a new fan would be needed for the coming age to help people get through hot summers using as little energy as possible.”

He also knew, however, that to realize this idea it would be necessary to fundamentally overhaul existing fan technology.

“The value a fan provides is ‘coolness,’ but it isn’t comfortable to be directly in the airflow of a conventional electric fan for too long,” he explains. “That’s why they swivel from side to side. But this only reduces the time the user is in the airflow, which also reduces coolness. What I wanted to make was an electric fan that would create airflow as pleasant as a natural breeze coming in through the window.”

New technology to create

a pleasant breeze

BALMUDA products always begin with a specific intent, followed by intense research.

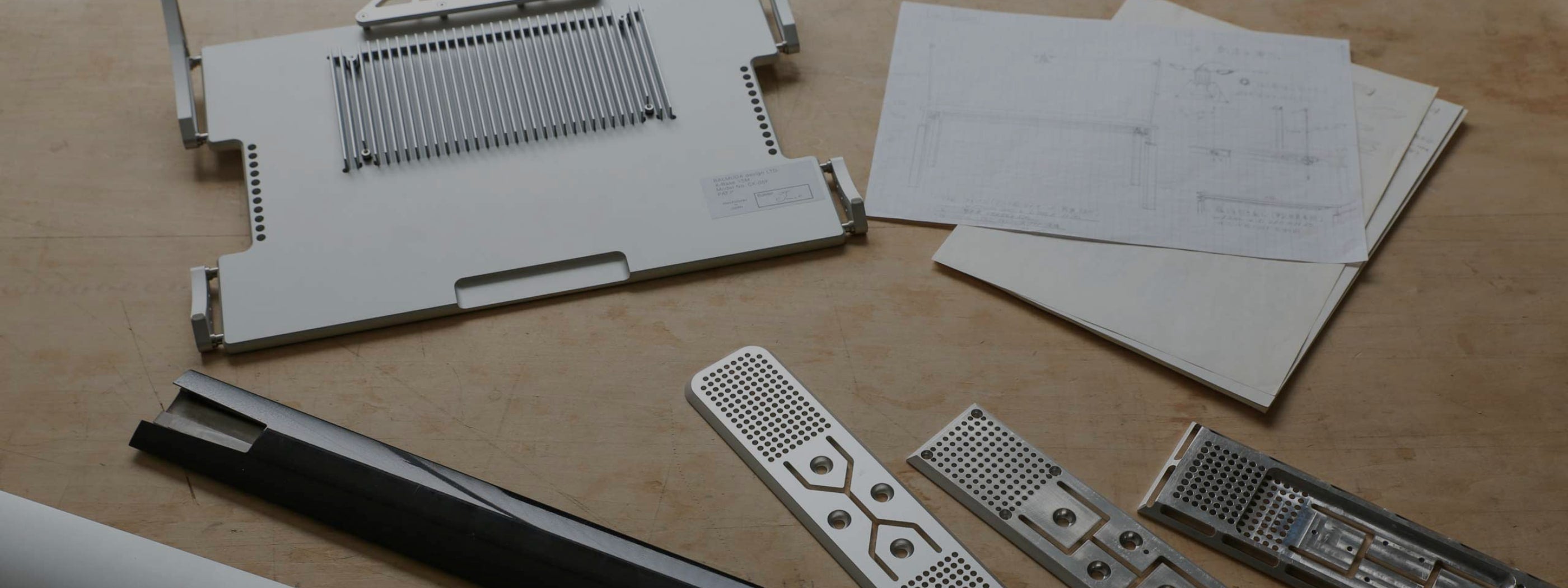

Gen began reading technical books on fluid aerodynamics and wing profiles. While he learned what wing shapes had the lowest air resistance, he didn’t discover any techniques to help recreate a natural air breeze. It seemed no one had ever taken up this challenge before.

Gen started studying air flow by utilizing a wind gauge to collect data from nature. He also studied the movement of air from existing fans.

The breakthrough came when he recalled something he had seen at one of the workshops he regularly visited. The artisans there would aim their fan at the workshop wall, breaking the spiral of wind and causing it to rebound as a two-dimensional plane. This, in turn, created the feeling of a natural breeze.

The question, then, was how to curve the wind from an electric fan? One day, when watching a television program with thirty children running a “thirty-one-legged race,” Gen was struck by a sudden realization: the faster children are dragged back by the slower ones. Perhaps the same thing can happen with air?

Driven by his latest hypothesis, he put two airstreams rotating at different speeds side-by-side. The faster one was dragged back by the slower and caused the two streams to collide. This discovery led to an entirely new dual-blade design. Gen experimented with dozens of blade types, carefully testing the movement of each. He even used a smoke machine to observe airflow inside a garage.

Finally, in April 2010, the GreenFan was complete. The technology it used was unique and entirely new.

Not only did the GreenFan offer different “airflow quality,” it also used a DC brushless digital motor to reduce power consumption -- as little as 4 watts per hour on the lowest fan setting (at the time). This newly developed “silent motor” kept the noise of the fan to just 13 decibels or less. As an electric fan, the GreenFan was unprecedented.

Many people were drawn to the GreenFan as a new way to create a pleasant breeze while keeping energy usage low. Despite a retail price above 30,000 JPY — unthinkable for an electric fan at the time — the GreenFan sold out its entire production run in both 2010 and 2011.

A low-power, low-noise electric fan that creates a natural breeze was the next stage for BALMUDA.