A team that supports the creative

Even after the GreenFan (an invention based on deep contemplation of what devices people needed), BALMUDA continued its research on pleasant coolness.

In April 2011, a redesigned version called the GreenFan 2 was released. In November of that year, the company unveiled the GreenFan Cirq, a circulating fan. In 2012 it released the GreenFan mini, a cordless model just 67% the size of the original.

Start from an idea, and actively incorporate it into a plan for a product that does not yet exist. Product development at BALMUDA aims to create tools for better living through creativity and technology. Based on this principle, the company’s development of its air conditioning appliances continued on.

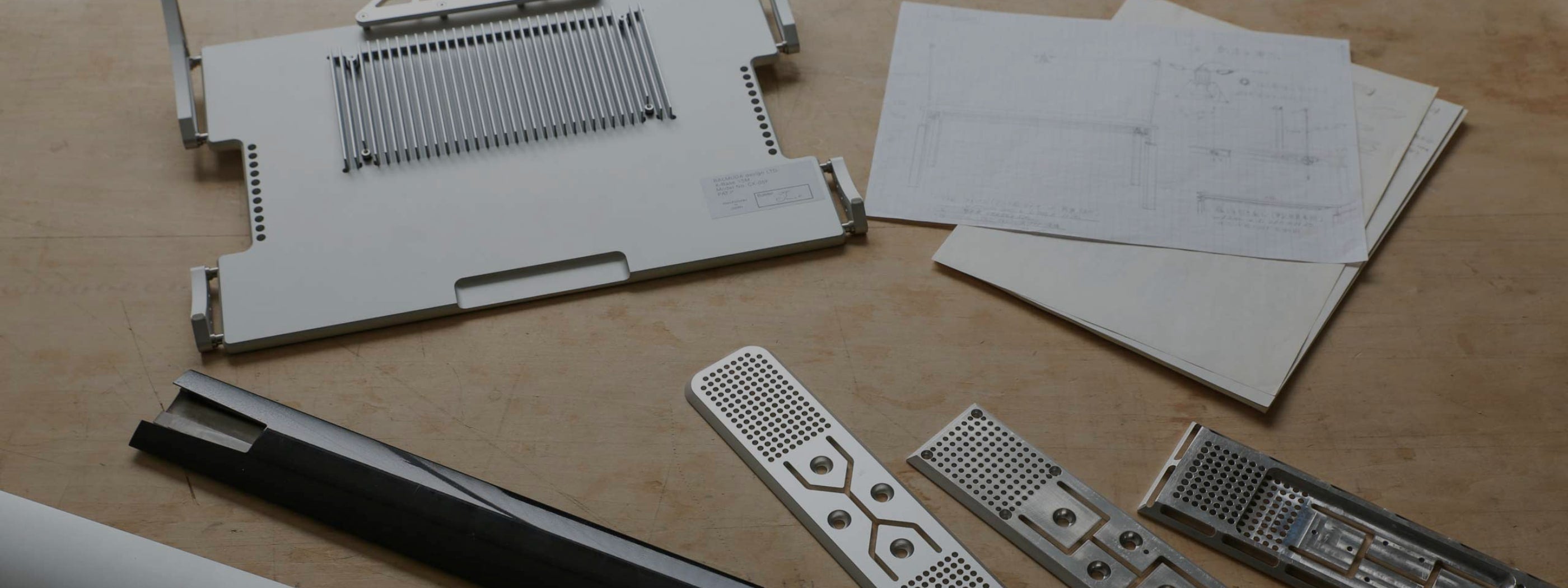

One important aspect of developing new products in this way is testing the technology. Creating a prototype is crucial for testing a product idea.

Following the release of the air purifier AirEngine (initially known as Jet Clean) in 2012, BALMUDA began to add to its team of engineers. Today it has dozens of engineers on staff, accounting for half of its total employee headcount. Spirited discussion with the design team helps technical and design development proceed hand-in-hand, each side supporting the other.

A perfect example of this partnership is the development of the AirEngline technology: the AirEngine uses a double fan structure combining a GreenFan-style propeller and a turbofan that delivers superior air suction with low energy consumption. By testing several dozen basic two-layered fan structures in prototype models, BALMUDA was able to create an air purifier that offered both strong suction and powerful airflow.

Hand-in-hand with the engineering team

Once the technology is established and product design is in progress, the final stage of development involves tests with working mock-ups produced on a cutting machine. Refinement and retesting continue until the development team is satisfied. For the AirEngine, in order to test the propeller construction, repeated experiments were also performed on the effect of the suction on dust, pollen, and other particles.

In 2013, BALMUDA unveiled the Rain, a humidifier without a detachable tank that can be filled directly from a kettle. They also introduced the SmartHeater, which has a radiator built using hollow aluminum for quicker start-up times. In the same year, the company also revealed its UniAuto technology for connecting BALMUDA products to smartphones and other devices.

Products like this are rooted in BALMUDA’s basic philosophy of development: the driving force for new projects lies precisely in the gap between the present and the future. “Imagining something that never existed, drawing a picture of the future — that’s the power of creatives. Nobody can decide what the future holds. Forget the common wisdom and keep thinking.”

Intentionally putting aside restrictions when coming up with new ideas means setting out to develop the necessary technology yourself when needed. BALMUDA’s engineering team spends 90% of its time on experiments, striving to create ever more useful tools that people need.

like no other" />

like no other" />